Fuel atomisation in airblast atomisers is one of the research topics within ESTiMatE. The selected methodology consists of a Volume of Fluid (VOF) approach to simulate the liquid film formation and its breakup by means of a Direct Numerical Simulation (DNS) framework. The novel approach proposed by Universitat Politècnica de València (UPV) is the inclusion of both the turbulence inflow and the liquid film thickness evolution upstream of the atomizer lip in the DNS simulation conducted with the ParisSimulator code (Aniszewski et al. 2021).

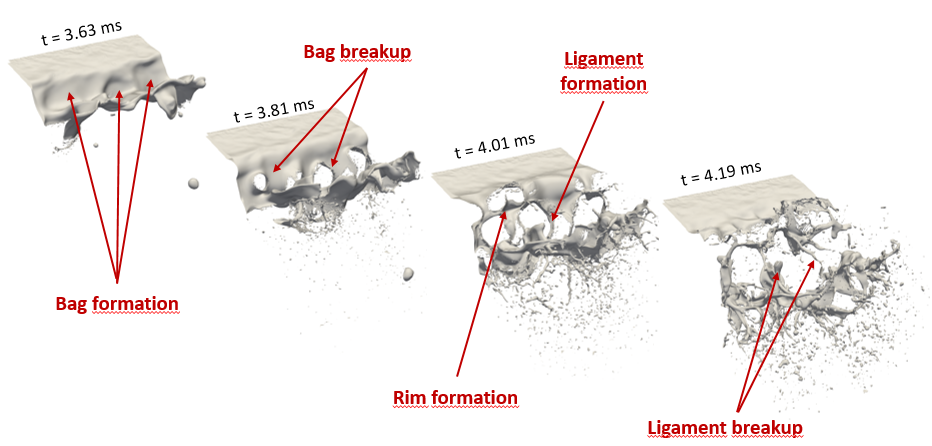

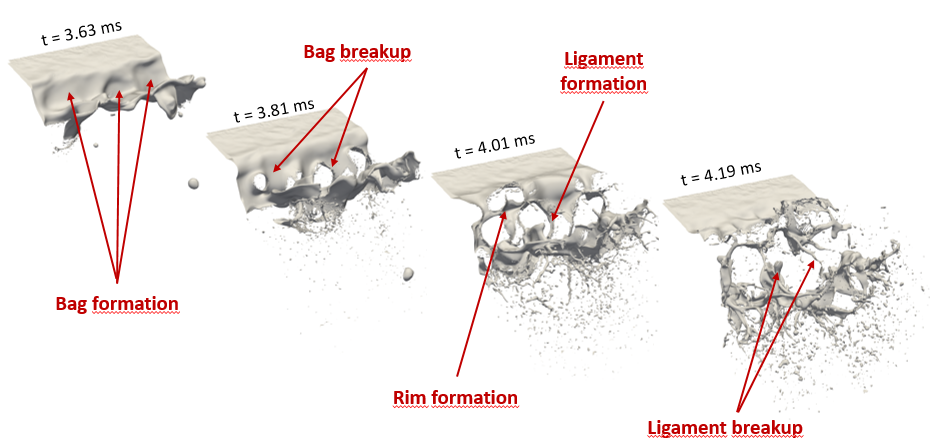

The research team at ESTiMatE conducted a simulation on Joliot Curie-AMD at GENCI at CEA (thanks to resources awarded by PRACE) replicating a reference operating condition experimentally studied at Karlsruhe Institute of Technology (KIT) (Chaussonet et al. 2019). Results from the simulation (see Figure 1) show that the proposed workflow successfully allows reproducing the breakup mechanism specific for prefilming airblast atomisers. This includes a stage of liquid accumulation behind the prefilming edge, which ends up shaping bags that simultaneously lead to two liquid structures: fine droplets directly produced by bag breakup, and rims that generate longitudinal ligaments that eventually break into larger droplets.

Figure 1. Qualitative evolution of the spray in the ESTiMatE VOF-DNS simulation reproducing the primary breakup mechanism of prefilming airblast atomizers

Quantitative results of this simulation workflow will be presented at the ICLASS 2021 International Conference on Liquid Atomization & Spray Systems, to be held online from August 30th to September 2nd. While the gain in predicting atomisation outputs has been marginal for the reference condition tested with a relatively thick prefilmer (230 micrometers, necessary for validation purposes), this workflow will show its full potential in the successive simulations of thinner prefilmer edges. In such configuration, more representative of the aero engine application, the liquid accumulation phenomenon loses relevance in favour of membrane sheet breakup, for which the liquid film evolution accounted for in ESTiMatE plays a driving role (Inamura et al. 2019).

References

Aniszewski, W., Arrufat, T., Crialesi-Esposito, M., Dabiri, S., Fuster, D., Ling, Y., Lu, J., Malan, L., Pal, S., Scardovelli, R., Tryggvason, G., Yecko, P., Zaleski, S., “PArallel, Robust, Interface Simulator (PARIS)”, Comput Phys Commun 263:107849, 2021.

Chaussonnet, G., Gepperth, S., Holz, S., Koch, R., Bauer, H.J., “Influence of the ambient pressure on the liquid accumulation and on the primary spray in prefilming airblast atomization”, Int J Multiphas Flow 125:103229, 2019.

Inamura, T., Katagata, N., Nishikawa, H., Okabe, T., Fumoto, K., “Effects of prefilmer edge thickness on spray characteristics in prefilming airblast atomization”, Int J Multiphas Flow 121:103117, 2019.