In view of the detrimental impact of soot on the environment and health, the development of low-emission combustion systems is a key challenge in modern-day combustion research. To address this challenge, numerical investigations with accurate predictive soot models are crucial in the design process of such future combustion devices. In this context, one of the key objectives of the ESTIMATE project is to develop a numerical framework by integrating detailed soot modeling approaches with turbulent combustion models for the prediction of soot formation in aero-engine relevant conditions. Within the project, coupling of Flamelet Generated Manifold (FGM) [1] tabulated chemistry with a discrete sectional method-based (DSM) [2] soot model has been achieved [3] to conduct numerical simulations of turbulent sooting flames. The use of the sectional soot model enables information on the soot particle size distribution, which is crucial for understanding the evolution of soot particles. To investigate the performance of the FGM-DSM framework in a model gas turbine combustor, the burner experimentally investigated at DLR [4] is retained. The burner presents a high-pressure Rich-Burn/Quick-Quench/Lean-Burn (RQL) combustion system. In the burner, gaseous ethylene fuel is injected into the combustion chamber through a central annular nozzle surrounded by a concentric swirling primary air coflow. Secondary air is supplied into the combustion chamber at a specific downstream position to create an RQL-type region for soot oxidation.

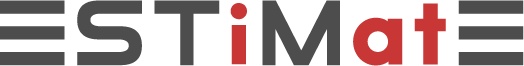

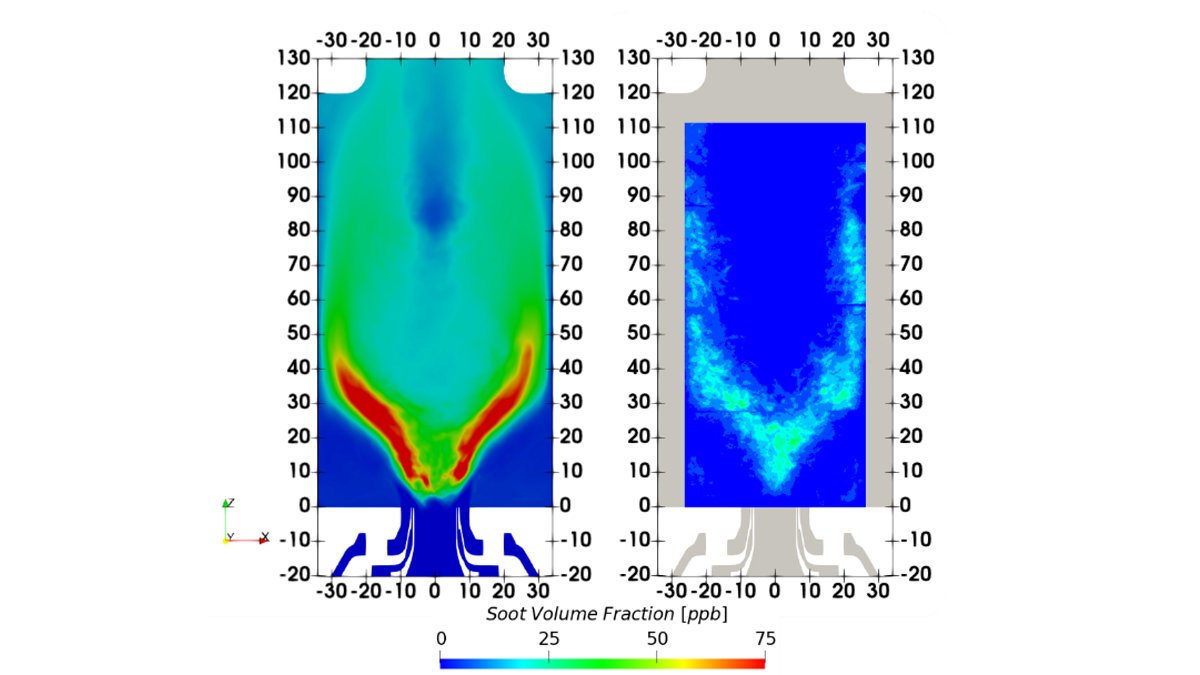

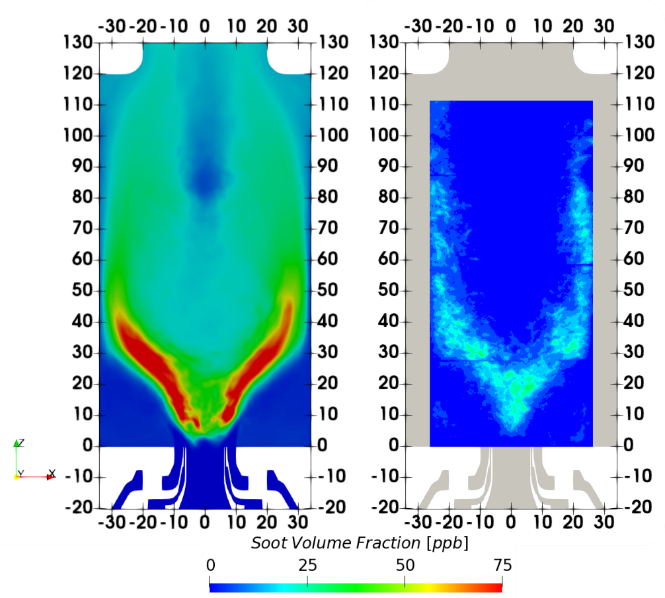

Researchers from UPV, TUE, and BSC are collaborating on a detailed numerical study of the DLR burner using Large-Eddy Simulation (LES). The simulations have been carried out using multi-physics reacting flow solver Alya. The sectional soot model has been applied in combination with FGM chemistry and a turbulence closure model based on presumed probability density functions. A chemical kinetic mechanism developed by USTUTT [5] is employed for gas-phase chemistry during flamelet table generation. Transport equations for soot mass fraction are considered with tabulated source terms to predict the concentration of soot. Prior to sooting flame simulations, the gas-phase flow and mixing characteristics are verified for the LES. The results for time-averaged fields for velocity and temperature show good agreement with the measurements. Furthermore, FGM-DSM provided a satisfactory qualitative and quantitative prediction for the soot volume fraction. At present, the impact of the heat-loss effect on soot formation is being investigated. The high-performance computing resources required for the simulations are allotted under the Partnership for Advanced Computing in Europe (PRACE) program.

References:

[1] J. van Oijen, and L. P. H. de Goey., Combust. Sci. Tech. 161, (2000) 113–137.

[2] C. A. Hoerlle, and F. M. Pereira, Combust. Flame, 203:407-423 (2019).

[3] A. Kalbhor, and J. van Oijen, Combust. Flame, 229 (2021) 111381.

[4] P. Geigle, R. Hadef, R., W. Meier, J. Eng. Gas Turb. Power, 136(2) (2014).

[5] A.Y. Ramirez-Hernandez, T. Kathrotia, T. Methling, M. Braun-Unkhoff, U. Riedel, Gas Turb. Power GTP-21-1384.