The reduction of soot formation in combustion systems is one of the main challenges in combustion research. Soot particles, formed during incomplete and inefficient combustion of hydrocarbon fuels, are one major contributor to global warming and pose a serious risk to human health. The understanding and ability to predict the soot formation and growth processes are crucial to design the next generation of sustainable combustion systems.

In ESTiMatE, the Institute for Simulation of Thermo-Fluid Systems (STFS) of the TU Darmstadt is developing a statistical approach, the so-called Quadrature-based Method of Moments, to describe the soot properties of reacting flows under aero-engine conditions.

The method has been applied in several studies [1-3]. In a recent work, “Experimental and numerical study on the effect of oxymethylene ether-3 (OME3) on soot particle formation” [4] the Quadrature-based Method of Moments has been employed to analyze the effects of oxygenated fuel blends, such as oxymethylene ethers (OMEs), on soot formation propensity.

In rich premixed OME3/ethylene flames, we have observed a significant reduction of large soot aggregate while the number of smaller particles remains comparable to reference flames with pure ethylene. OMEs belong to the class of synthetic fuels, i.e. fuels that can be produced by recycling CO2 via electrolysis using renewable energies, contributing to the overall greenhouse gas balance. Such synthetic fuels represent a promising alternative to reduce the carbon footprint of actual combustion devices. However, further research is in progress to achieve a comprehensive understanding of the combustion and sooting characteristics of alternative fuel candidates and their blendings, such as oxygenated fuel- or hydrogen- blended flames.

In the first phase of ESTiMatE, a kerosene-surrogate with relevant thermo-physical and chemical properties of typical aviation kerosene has been defined. The University of Stuttgart is developing a detailed kinetic description of the chemical reaction for the kerosene surrogate, which will be employed in the numerical simulations.

To develop a suitable soot model for aero-engine conditions, experimental measurements of laminar flames have been conducted at Karlsruhe Institute of Technology (KIT), Engler-Bunte-Institute.

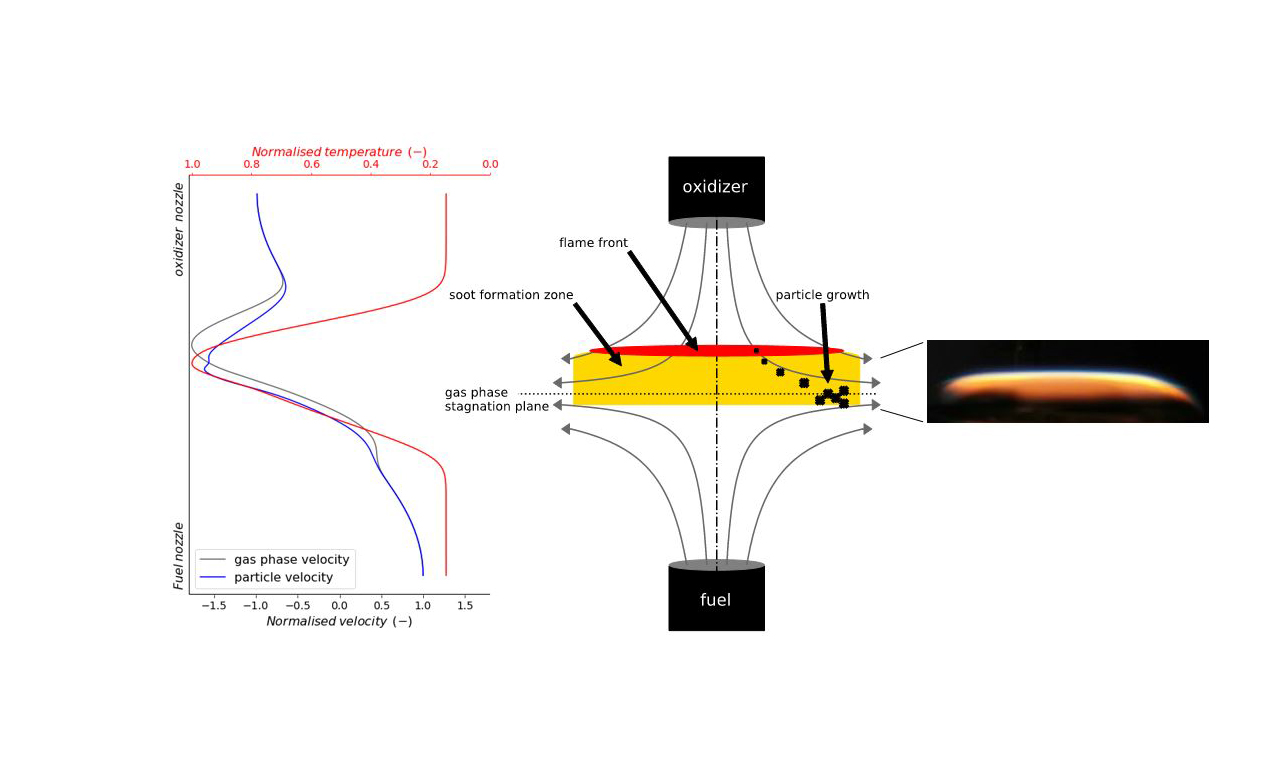

Figure 1 shows a counterflow diffusion flame, chosen as the benchmark case for model validation: in the center, a schematic representation of the burner is shown, while a snapshot of the experimental study can be seen on the right [5]. Here a soot formation configuration flame is considered, which consists of a lightly diluted fuel diffusing into a stream of an opposed oxidizer. The flame front stabilizes on the oxidizer side of the stagnation plane at stoichiometric conditions. Soot is formed close to the flame front and is transported with the gas phase towards the direction of the gas phase stagnation plane. Due to thermophoretic effects, soot particles can cross the gas-phase stagnation plane and continue to grow under conditions containing no oxidizing species.

An example of the temperature and velocity profiles for the gas and solid phase in the counterflow flame configuration is shown in the plot on the left of Fig. 1.

In the second phase of ESTiMatE, laminar flames at elevated pressure and turbulent swirling flames will be studied to investigate model performances under aero-engine relevant conditions.

[1] Salenbauch, S., Cuoci, A., Frassoldati, A., Saggese, C., Faravelli, T., & Hasse, C. (2015). Combustion and Flame, 162(6), 2529–2543. https://doi.org/10.1016/j.combustflame.2015.03.002

[2] Salenbauch, S., Sirignano, M., Marchisio, D. L., Pollack, M., D’Anna, A., & Hasse, C. (2017). Proceedings of the Combustion Institute, 36(1), 771–779. https://doi.org/10.1016/j.proci.2016.08.003

[3] Salenbauch, S., Sirignano, M., Pollack, M., D’Anna, A., & Hasse, C. (2018). Fuel, 222(February), 287–293. https://doi.org/10.1016/j.fuel.2018.02.148

[4] Federica Ferraro, Carmela Russo, Robert Schmitz, Christian Hasse, Mariano Sirignano, (2021), Fuel, Volume 286, Part 1, 2021, 119353, ISSN 0016-2361, https://doi.org/10.1016/j.fuel.2020.119353.

[5] Petros Vlavakis, Alexandra Loukou, Chair of Combustion Technology, Engler-Bunte-Institute, Karlsruhe Institute of Technology (KIT)